Key takeaways:

Pricing HVAC jobs for profitability requires a careful, step-by-step approach. Here’s how to ensure you cover costs and stay competitive:

- Calculate all job costs accurately. Break down every project into labor, materials, and overhead, using historical timesheets and up-to-date expense tracking to determine your true costs for each job.

- Choose the right pricing strategy. Evaluate flat rate, time and materials, and hybrid models to see what fits best for your typical jobs—flat rate for predictable work, T&M for complex tasks, and hybrid for added flexibility and protection of your margins.

- Research your competition and market demand. Gather local competitor pricing and survey customers to set rates that reflect both local willingness to pay and the unique value your business offers.

- Add appropriate markup to reach profit goals. After tallying up all costs, apply a markup that meets your target profit margin—typically 20% or higher—so your pricing supports both competitive wages and long-term business growth.

- Account for taxes and customer negotiations. Decide whether to include taxes in your rates or list them separately, and develop strategies for handling discount requests, such as offering value-added upsells without compromising your bottom line.

- Send professional, detailed estimates. Provide clear, itemized quotes that help customers understand what they’re paying for, and always include company branding and terms to boost trust and win more jobs.

For more expert tips on pricing, profitability, and running your service business, sign up for the Jobber Newsletter. Join here.

Pricing your HVAC services appropriately is key to keeping your business running and growing. That said, it can be difficult to know how to price HVAC jobs when the work itself is fluid and unpredictable.

To stay profitable without driving customers away, you need to understand your costs, know what your competitors are charging, and use this information to strategically mark up your jobs.

Follow this HVAC pricing guide to learn how to set the best service prices for your business.

1. Calculate your job costs

Knowing how much you need to spend helps you cover your essential costs and turn a profit with your pricing. Divide your costs into three categories: labor costs, material costs, and overhead.

Determine your HVAC labor rates

Your labor rate is how much you pay yourself, your contractors, subcontractors, or employees for a job. To ensure you’re paid fairly for your work, factor this number into your installation cost estimate, no matter your pricing strategy.

Here’s how you can calculate your total labor cost for a job:

Labor hours x hourly labor cost

- To calculate labor hours: Multiply the time spent on a job by the number of techs you need on the job. (E.g., 3 hours x 2 people = 6 hours)

- To calculate your hourly labor cost: Add up each HVAC technician’s hourly salary, plus taxes, workers’ compensation, and any other employee-related expenses. A markup of 20–30% is a reliable rate for hourly labor costs. (E.g., $28 + 20% = $33.60)

- When you multiply your labor hours by your hourly labor cost, you’ll get a total labor cost you can add to your final cost estimate. (6 x 33.60 = $201.60)

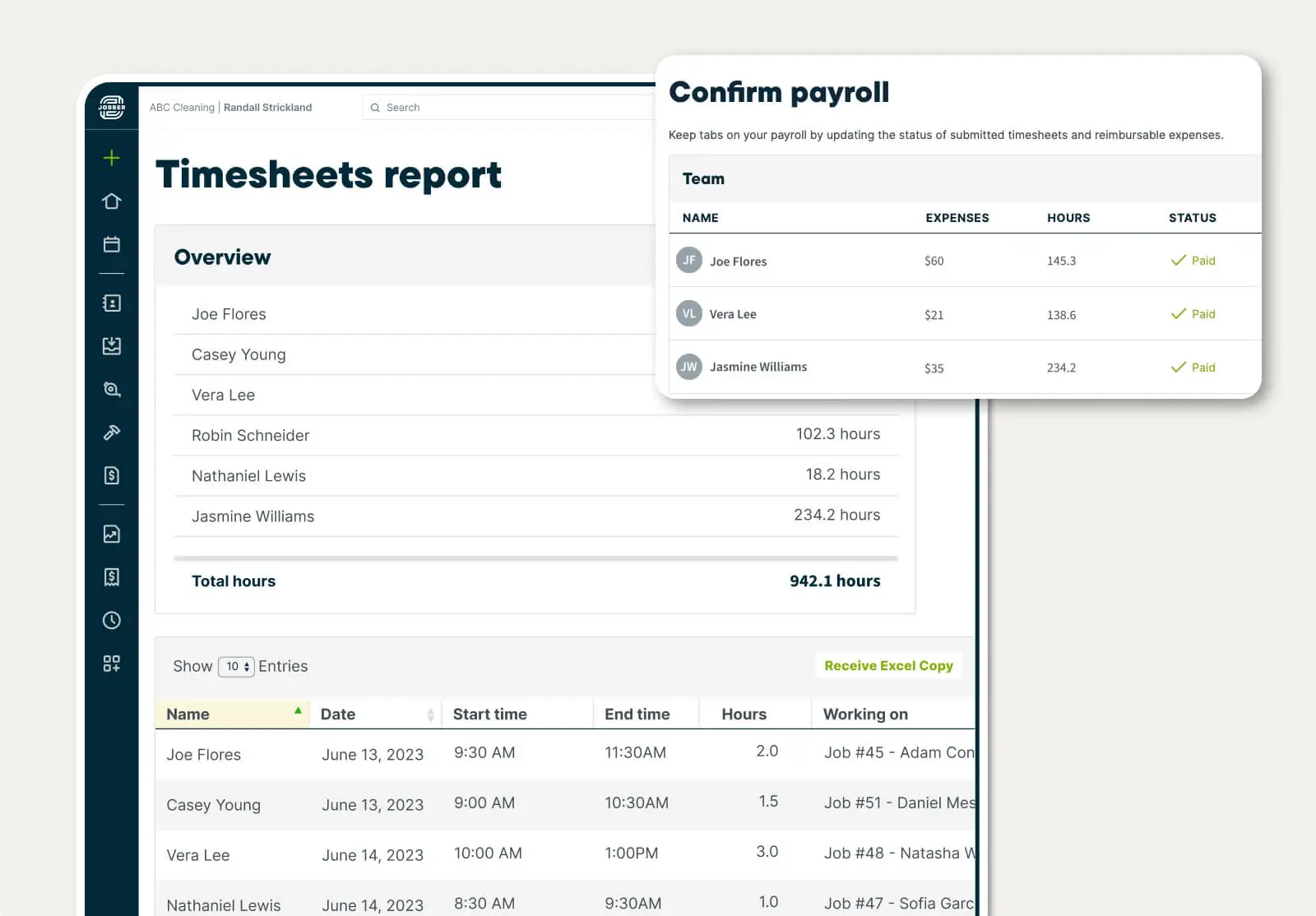

To get the most reliable estimate of how long a job will take, look at your timesheets for past jobs. If you’re already tracking time with HVAC software like Jobber, you can see pre-built time tracking reports showing hours worked in the field, work history, and job notes:

Calculate material costs

Material costs include the supplies needed to complete an individual job—think new equipment (like an AC unit or thermostat), replacement parts (like fuses and drain pans), or brand-new HVAC tools.

Once you have a clear scope of the work:

- List all the materials you need for the job

- Add the cost of each material

- Add markup to each material cost

Adding markup to new materials you purchase helps you offset overhead costs without cutting wages or adding huge hourly labor rates to your HVAC estimates.

Follow an HVAC parts markup chart to get started. The average markup on HVAC equipment is between 25 and 50%, and 100% or higher for spare HVAC parts and materials.

Pro Tip: Use expense tracking software to keep a record of parts and other job-related materials. Jobber automatically calculates profitability for each job based on every on-the-job expense you’ve tracked.

Calculate overhead costs

Overhead is the combined cost of everything else you need to run your HVAC company, outside of materials and labor. Overhead costs are not specific to an individual job and include expenses like vehicle leases, licensing fees, cell phone bills, HVAC business insurance, office space, and uniforms.

Your overhead costs are likely monthly or annual, so it can be hard to calculate them for one specific job. Estimate overhead costs for one specific job by finding your hourly overhead rate.

To calculate your overhead costs per hour, use this formula:

Total monthly overhead ÷ # of billable hours per week

- Calculate your monthly overhead fees (E.g., $8,000)

- Determine the number of weekly labor hours worked (E.g., 400 hours)

- Divide your weekly overhead cost into hours worked for an hourly overhead cost ($8,000 ÷ 400 = $20)

- This means that for every labor hour, you need to charge $20 to cover that cost

- Multiply the hourly overhead cost by the number of labor hours for the job ($20 x 260 = $5,200)

2. Choose a pricing strategy

There are a few different methods for deciding how much to charge for HVAC services. Flat rate and time and materials are two industry standards, and hybrid pricing is a method that combines the previous two.

Learn the pros and cons of each pricing approach here before choosing what works best for you.

Flat rate pricing

With flat rate pricing, you set a fixed price for the job, no matter how long it takes. Your flat fee should account for the costs of completing the HVAC job, like ductwork purchased and freon used. But you won’t include line items for labor costs or actual material costs on your estimate.

Flat rates reward efficient work—the faster you go, the more profit you make. Plus, customers will know the exact cost upfront, with no surprises when the job is done.

Here’s how you calculate it:

Total cost = (estimated labor hours x hourly rate) + (estimated cost of materials x markup)

For example, let’s assume you’ve estimated that an A/C tune-up takes at most an hour, the average cost of materials is $20, and you want to factor in a 25% markup. This is what the flat rate for your A/C tune up might look like:

Total cost = (1 hour x $80/hour) + ($20 x (1 + 0.25)) = $105

On the other hand, some customers assume you’re overcharging if there are no line items explaining your rates. An HVAC tech might also earn less than their regular hourly rate if a job takes longer than expected.

HVAC flat rate pricing is usually ideal for these types of work:

- Common repairs: Repairs like refrigerant leaks and thermostat malfunctions are generally straightforward and predictable. Costs for these jobs tend to be easier to factor into a flat rate.

- Routine maintenance and inspections: These typically follow a standard operating procedure, whether you’re using an HVAC inspection checklist or have memorized the steps from years of experience. You won’t have unexpected work that eats into your labor costs, since you’ll charge separately for any repairs or replacements.

- HVAC system installations and replacements: These include the cost of a brand-new HVAC system, which depends on supplier prices, but should be a predictable cost. Add your markup, plus your labor and overhead costs to get your installation rate.

Set flat rates for all your services and add them to your HVAC price book to save time when estimating jobs. To help yourself out, include a price range for every possible job, from high-efficiency furnace installations to a simple thermostat replacement.

| Pros of Flat Rate Pricing | Cons of Flate Rate Pricing |

| Easy for customers to understand and budget for | Requires accurate job costing (labor, parts, overhead) up front |

| Techs can complete more calls per day without earning less per job | Risk of losing money on jobs that take much longer than estimated |

| Reduces price anxiety and bill disputes because there’s no meter running on labor time | Can appear more expensive than competitors who advertise low hourly rates |

| Supports consistent margins on routine, repeatable work | Requires a process and training so every tech uses the price book correctly |

Time and materials pricing

The time and materials (T&M) method involves pricing a job based on the time it takes, the HVAC contractor’s hourly rate, and the cost of the materials plus markup.

Here’s how you calculate it:

Total cost = (actual hours worked x hourly rate) + (cost of materials x markup)

For example, assuming a 25% markup on materials for a custom ductwork project, this is what that formula might look like:

Total cost = (2 hours x $80/hour) + ($600 x (1 + 0.25)) = $910

Pricing by the hour lets you compensate technicians for the exact amount of time a job takes—and it shows customers exactly what they’re paying for. It’s good practice to give customers a quote up front with estimated hours so they can get a sense of what the actual cost will be.

However, the longer a job takes, the more money it will cost the homeowner. A technician who’s slow or makes mistakes on the job will drive up your invoice total, and getting paid for the job hourly doesn’t incentivize faster work.

T&M pricing is best suited for these types of jobs:

- Complex or unusual repairs: Estimating the labor hours it’ll take to diagnose and repair less common HVAC system problems is more challenging. Charging by the hour ensures you’re compensated fairly for the extra time and specialized skills you need for the job.

- Custom installs: Pricing by the hour helps you profit on labor that’s difficult to predict ahead of time—think systems that need custom sheet metal ductwork or have unique architectural features.

- Emergency calls: Without an initial inspection to understand the root cause of the problem, emergency HVAC service calls can be time-consuming and complicated. These calls also take time away from planned work and can happen after hours, so you should ensure you are paid appropriately for this premium service.

| Pros of T&M Pricing | Cons of T&M Pricing |

| Simple to calculate and explain | Unpredictable final price can create sticker shock and erode trust |

| Flexible for complex or unpredictable jobs where the scope may change | Techs have less incentive to be efficient, which can reduce margins |

| Reduces risk of losing money on time‑intensive or unusual jobs | Harder to sell at higher hourly rates |

| Useful for commercial or project work where scopes are negotiated and documented in detail | Creates more billing admin work to track time and log materials |

Hybrid pricing

Hybrid pricing sits right in the sweet spot for pricing HVAC jobs, blending the flat-rate and T&M models. Here’s how you use this approach:

- Use a flat rate to cover tune-ups, spring/fall cleanings, common repairs, and replacement work where you know your average time, parts, and margin

- Use time and materials for curveballs, like custom duct transitions, major retrofits in old homes, or any job where you know there’ll be unknowns

This blend protects your profit margins. Flat rates lock in steady gross profit on routine jobs, and T&M keeps you from losing money when a job drags on or forces your tech to MacGyver a solution because the home is so old.

Here’s how you calculate it:

Total cost = flat rate portion of the job + T&M portion of the job

Using the two previous examples, let’s assume the job involves both the A/C tune-up and custom ductwork. This is what the hybrid price might look like:

Total cost = [(1 hour x $80/hour) + ($20 x (1 + 0.25))] + [(2 hours x $80/hour) + ($600 x (1 + 0.25))] = $105 + $910 = $1,015

Over time, refine your hybrid approach with real data. Pull your job history once a quarter, for example, and ask yourself:

- Which flat-rate tasks consistently hit strong margins?

- Where do you keep going over on labor?

- Which repair types always balloon into something ugly?

Anything that consistently runs long could shift to T&M. Anything that stays tight on labor could settle into a flat rate.

| Pros of Hybrid Pricing | Cons of Hybrid Pricing |

| Balances predictability and flexibility by using a flat rate on standard jobs and T&M on unpredictable work | Requires clear internal rules about when to use each approach so techs don’t apply the wrong model |

| Helps protect profit margins | More complex to explain and manage than using a single pricing model |

| Lets you adapt to different customer types (e.g., flat rate for routine service, T&M for project work) | Customers can be confused if they don’t understand which parts of the job are flat rate vs. T&M |

| Can improve customer trust by giving firm prices where possible and being transparent about open-ended work | Requires good job costing data so you know which tasks should be flat rate and which should be T&M |

3. Research competitor rates

Call or request HVAC proposals or estimates from competitors to find out what average HVAC contractor prices are in your service area.

Be sure to review new and established HVAC businesses to understand how pricing varies based on experience.

Browse competitor websites and take note of the services they offer—and how similar they are to yours. Pay attention to things like:

- Whether they offer residential or commercial HVAC services (or a mix of both)

- The size of their HVAC jobs

- Size of the company

- How long they have been in business

Established, commercial-focused HVAC companies may charge higher rates because they need more equipment or employees. Alternatively, small, residential HVAC startups may offer lower rates because they have less overhead.

If you’re just starting out your HVAC business, try to price yourself somewhere between the highest and lowest prices. If you have a specific market in mind, like high-end customers, set your pricing for that market.

Keep an eye on what your competition charges even after you’ve set your service pricing. As market rates change and the costs of labor and materials shift, you’ll have to adjust your own pricing accordingly.

Gauge what local customers are willing to pay

In addition to competitor research, your prices should also reflect what local customers can afford. Here are some ways to do that:

- Survey recent customers directly. Ask what they consider a fair price for common services and what they expect from a premium vs. budget-friendly service business.

- Poll people in online community groups and social media. Ask homeowners what they’ve paid for HVAC work, what motivated them to choose a particular company, and a price level caused them to hesitate.

- Review customer feedback for competitors. Check review platforms like Google and Yelp. Look for mentions of being too expensive, if customers think the pricing is a good deal, or if there are any complaints.

- Track customer interests and needs. Look to see which of your discounts, bundles, and plans get the most traction. If premium maintenance plans sell well, there could be a willingness to pay more for the value. If low-priced specials hardly sell, the discount might not be big enough, or there may not be demand for the service.

- Do a “price test” occasionally. Offer two price points for a small group of your customers and monitor conversions and pushbacks. This can help identify the local price ceiling before making any big changes across the board.

Average HVAC service prices

The following costs are typical average ranges that HVAC companies charge in the United States for residential, according to data from HomeAdvisor:

| HVAC Service | Typical Cost Range |

| Furnace installation or replacement | $1,700–$10,000 |

| AC unit installation or replacement | $3,900–$7,900 |

| AC unit repair | $200–$1,000 |

| Heat pump replacement | $4,200–$7,600 |

| Heat pump repair | $200–$2,000 |

| Boiler replacement | $1,800–$9,000 |

| Boiler repair | $200–$600 |

4. Add markup to your total cost estimate

Add your material, labor, and overhead costs to get your total cost estimate. This estimate is approximately how much you’ll spend on the job.

Then, add markup to this total. Markup is how much you charge on top of your costs to meet your target profit margin for the job.

Your profit margin is going to be helped by selling at the right price and being efficient in the field and not having too much overhead.

HVAC businesses typically add markup to materials and services separately. For example, you might buy parts in bulk and charge a markup on them, while also adding a markup on top of labor and overhead.

To decide the total price you should charge for your HVAC services:

- Make your total cost estimate (material + labor + overhead costs)

- Choose your desired profit margin

- Calculate your markup

- Cost estimate + markup = total price for the job

Let’s say your costs total $3,600, and you’re aiming for an operating profit margin of 25%. That means the cost of your job should make up 75% of the total price.

To calculate the total price, use the formula:

Price = Cost ÷ (1 – profit margin)

So, the total price you should charge to achieve a 25% profit margin will be:

Price = $3,600 ÷ (1 – 0.25) = $3,600 ÷ 0.75 = $4,800

You’ll need to charge a markup of $1,200 on top of your cost of $3,600 to reach your 25% profit margin.

What is the ideal profit margin for HVAC companies?

The ideal profit margin for HVAC businesses is typically 20% or higher, but it depends on your goals, your service location, and the kinds of services you offer.

Figure out how much you need to profit annually to pay yourself and your crew competitive wages, buy and maintain quality equipment, market your services, and operate your business however you want. If you are more aggressive with your profit margins, 40-60% profitability is achievable.

5. Factor in taxes

To cover your business taxes, add them in when you’re charging for HVAC work. You have two options when it comes to quoting your customers for your HVAC services:

- Include taxes in your pricing model

- Charge taxes separately on each invoice

Most businesses list taxes as a separate line item on each quote or invoice because it’s easier to calculate and manage. That means setting a specific price for a service, like $80 to repair a flame sensor, and then charging taxes on top of it.

If you decide to include taxes in your pricing, you need to make sure they don’t cut into your profit, especially if tax rates change.

6. Handle customers who negotiate

Eventually, you’ll come across a client who wants a deal. But whether you can give one to them depends on a few factors.

Before you offer discount pricing to a customer, you should consider:

- How much you’ll profit from the job

- If you can offer an upsell at a discount price instead

- If you can provide a different service within their budget instead

Next, figure out why they’re asking for a discount. Are they on a tight budget or just hunting for a deal? Helping a customer out in a tough spot can build loyalty, but you don’t want to set unreasonable expectations for future work either.

Try offering a price guide with a few equipment or service options at different prices using a good-better-best HVAC proposal. Or help your customer pay in installments by adding consumer financing options to your quote.

READ MORE: Learn how to write an HVAC service contract and what to include in them

If they want a discount to get a lower price, try keeping the base service the same but upselling an additional service at a discounted price. For a furnace repair, for example, offer your customer a cleaning service for less than your usual price.

This way, you still get paid for the initial job (where you likely have the least wiggle room), and the customer feels like they got a deal.

We just have to be curious and care. When I’m talking to a prospect, I really want to understand why they want to do something.

And then I have to care enough to give them the best solution for that.

By the way, remember to use good HVAC CRM software to manage all of your customers (including the difficult ones who like to negotiate).

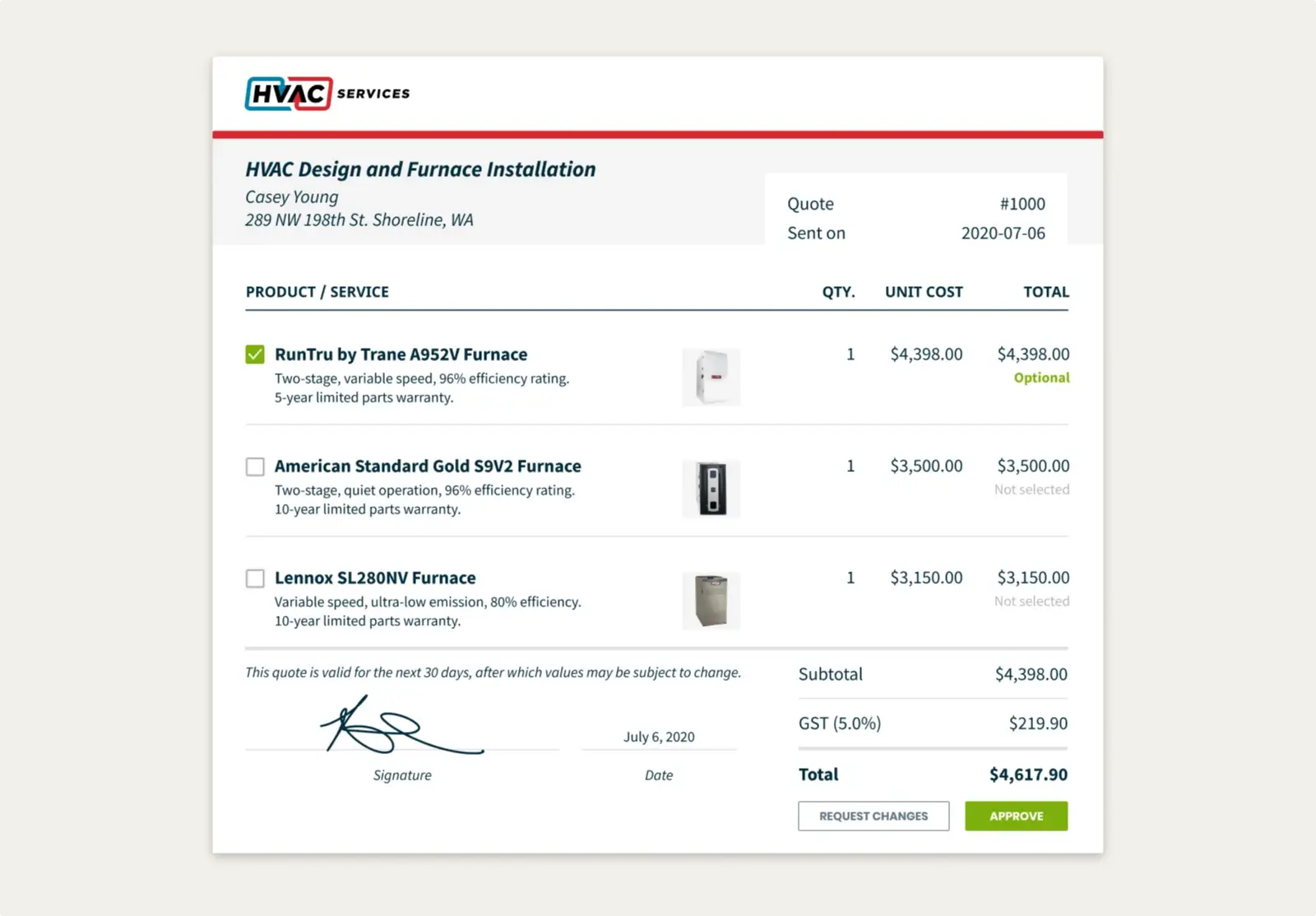

7. Build an accurate HVAC estimate

Understanding how to estimate HVAC jobs and send detailed quotes will help you win jobs, set clear expectations for your customers, and drive profit.

A detailed quote should describe all the work you’ll do before, during, and after the HVAC service call.

It also needs to look professional and include you and your client’s contact details, your company branding, terms and conditions, and any special discounts or rates.

Easily add that level of detail with quotes in Jobber, helping you create and send professional estimates to convert leads and win more jobs.

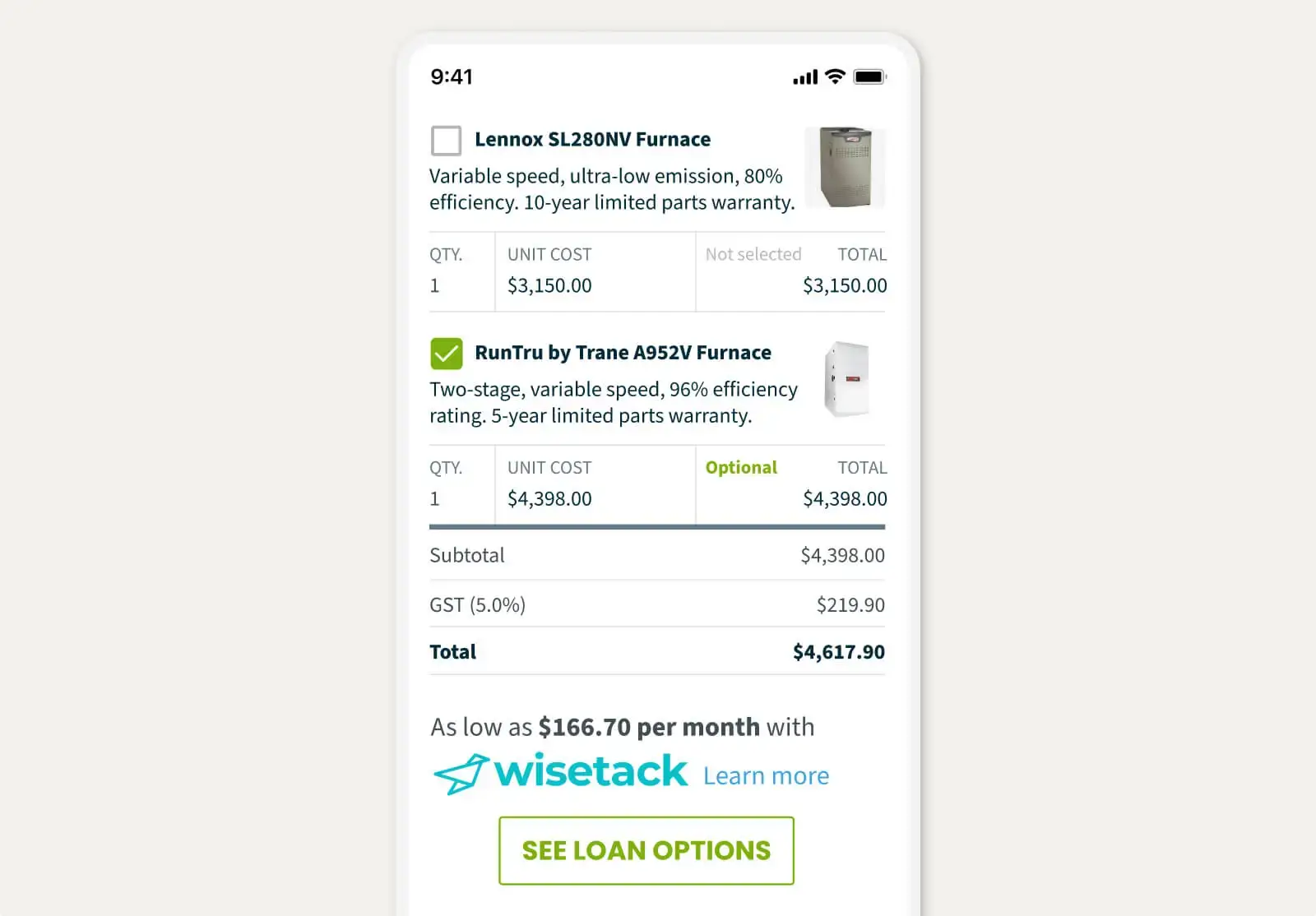

With Jobber, you can add optional line items to your estimates to suggest premium HVAC units or maintenance add-ons. Your customer can select the items that they want to add and track the updated total at the end of the estimate.

To improve your win rate, you can schedule automated follow-up emails or texts to remind customers of the sent estimate.

I 100% recommend you try Jobber.

It’s so much easier, saves you time, saves your business money, and makes things all around easier. Your customers will enjoy it, and so will you.

Pro Tip: Don’t be afraid to ask for deposits when sending quotes to help protect your bottom line. Take it from HVAC service pro Adrian Garcia of Reliable Kitchen, who recommends asking for deposits from new customers you haven’t worked with, so you don’t risk losing money. Or, for high-ticket jobs, where you want the customer to cover the equipment. This will help keep your cash flow healthy and avoid your money getting tied up ordering furnaces or new equipment for big jobs.

Originally published in November 2020. Last updated on December 16, 2025.

Frequently Asked Questions

-

HVAC companies typically mark up equipment (parts) by 25-50% for larger units and 100-300% for smaller parts.

For example, a $2,500 air conditioning unit could be marked up 25% to $3,125. And a smaller part, like a $20 capacitor, could be marked up 100% to $40.

If you want to use a single markup across the board for all parts, use at least 100% (double what you paid). A higher percentage might not be right for your business and your target customers.

-

Contractors charge an average of $10 to $25 per linear foot for ductwork installation, with a total average cost ranging from $453 to $2,185.

However, there are several factors that will determine how you’ll price ductwork jobs, including:

• Home size and layout: Bigger homes (or those with odd transitions) need more duct and more labor

• Location in the home: Attics and crawlspaces can slow you down, while basements and open ceilings are easier and faster

• Materials: Flex, insulated flex, and rigid metal each hit your budget differently

• Complexity: A tricky layout adds time and fittings -

Contractors often charge $65-$100 per hour for basic maintenance, and up to $200+ for emergency repairs and commercial work.

However, there are several factors to consider when deciding how much to charge for HVAC work, including:

• Location: Rates run higher in metro areas where fuel, rent, and payroll hit harder

• Experience: Techs with installation expertise or advanced diagnostics training can command stronger hourly rates

• Overhead: Your hourly price has to account for payroll, insurance, trucks, fuel, tools, and any costs that keep your business running

• Demand: During peak seasons (likely summer and winter) when your phone’s constantly ringing on top of a busy schedule, you can charge more -

Many pricing mistakes start with underestimating, such as matching a competitor instead of building rates from actual labor hours and job costs. Hidden labor costs lie in installs that aren’t as simple as expected, or in projects with difficult access.

You’ll also see problems when overhead gets ignored, like if you don’t charge enough to cover things like insurance, vehicles, and tools. And an estimate that’s built on outdated prices or “off the cuff” numbers can lead to the project only breaking even (or worse).

-

Calculate your labor cost for a job by multiplying the number of hours worked by the number of techs on the job and then multiplying by your hourly rate.

For example: 3 hours per person x 2 people x $80/hour = $480

-

Start by calculating your total job costs, then work up to the final price for the project. Break costs into labor, materials, and overhead:

• Estimate labor hours and multiply by your fully loaded hourly rate (wages including taxes and benefits)

• List all required materials and apply an appropriate markup

• Allocate overhead by using an hourly overhead rate multiplied by the job’s billable hours.

Add those three together to get your total cost. Then divide by (1 – your target profit margin) to get the final price. For example, if your total cost is $3,600 and you want a 25% margin, the price for the customer will be $4,800.